Green Energy Inexp CO. is proud to be one of the leading charcoal suppliers from Vietnam with superior quality and modern production processes. To ensure the highest quality products, we follow an 9-step detailed and strict charcoal production process, from raw material selection to carbonization.

Throughout the production process, the workers at Green Energy Inexp CO maintain high focus to achieve the best efficiency. Additionally, we carefully inspect the equipment and kilns before starting each step. Let’s continue to explore the detailed high-quality charcoal production process at Green Energy Inexp CO step by step:

Step 1: Prepare Ingredients

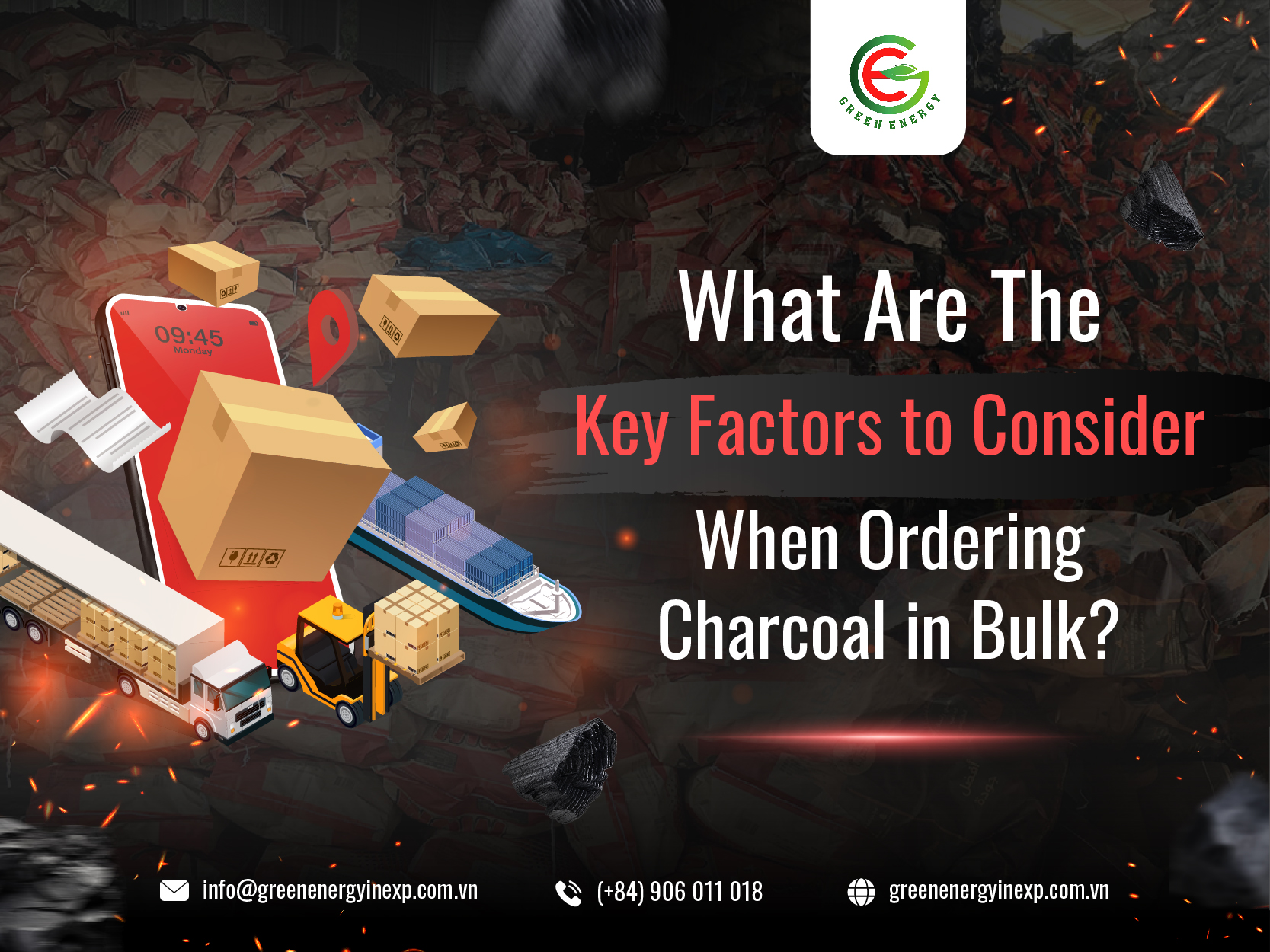

The main ingredient for producing charcoal is wood from sustainable and high-quality trees. We carefully select types of wood to ensure the finished charcoal has high hardness and heat content. The wood is harvested from areas certified for environmental protection, helping to maintain ecological balance and forest protection.

Step 2: Cut the Wood into Equal Length Pieces

After gathering the wood, the next step is to cut the wood into pieces of uniform length with standard dimensions: Length: 90-95cm, Diameter: 5-20cm. This step sets the foundation for the entire production process, ensuring that the burning and carbonization processes occur evenly, resulting in consistent quality charcoal.

Step 3: Load the Wood into the Kiln

The cut wood pieces are carefully placed in the kiln to ensure good air circulation and achieve the highest burning efficiency. Air circulation is key to ensuring an effective burning process.

Preparing the kiln before loading wood:

- Clean the kiln thoroughly, removing any debris, ash, or leftover charcoal from previous batches.

- Check the kiln’s ventilation system to ensure proper airflow during carbonization. Good ventilation helps ensure even heating and efficient conversion of wood to charcoal.

Once the kiln is ready, our workers load the wood into the kiln with proper technique:

- Step 1: Start by placing large wood pieces at the bottom of the kiln to form a solid base.

- Step 2: Arrange the wood in a crisscross or circular pattern to allow efficient air circulation through the gaps between the pieces, promoting burning and carbonization.

- Step 3: Stack the wood layers alternately, changing the grain direction to avoid collapse.

Tips for stacking wood to ensure good airflow:

- Create small gaps between the wood pieces to facilitate air circulation inside the kiln. These gaps allow air to move easily through the wood stack, promoting burning and helping the wood burn more evenly.

- Do not pack the wood too tightly as it can obstruct the carbonization process. Airflow is crucial for effective burning, so ensure enough space for air to move freely through the wood pieces.

- Occasionally insert small or vertical wood sticks into the wood stack. These sticks create natural ventilation channels that help release gases produced during carbonization.

- Distribute the ventilation channels evenly to maintain even heat distribution.

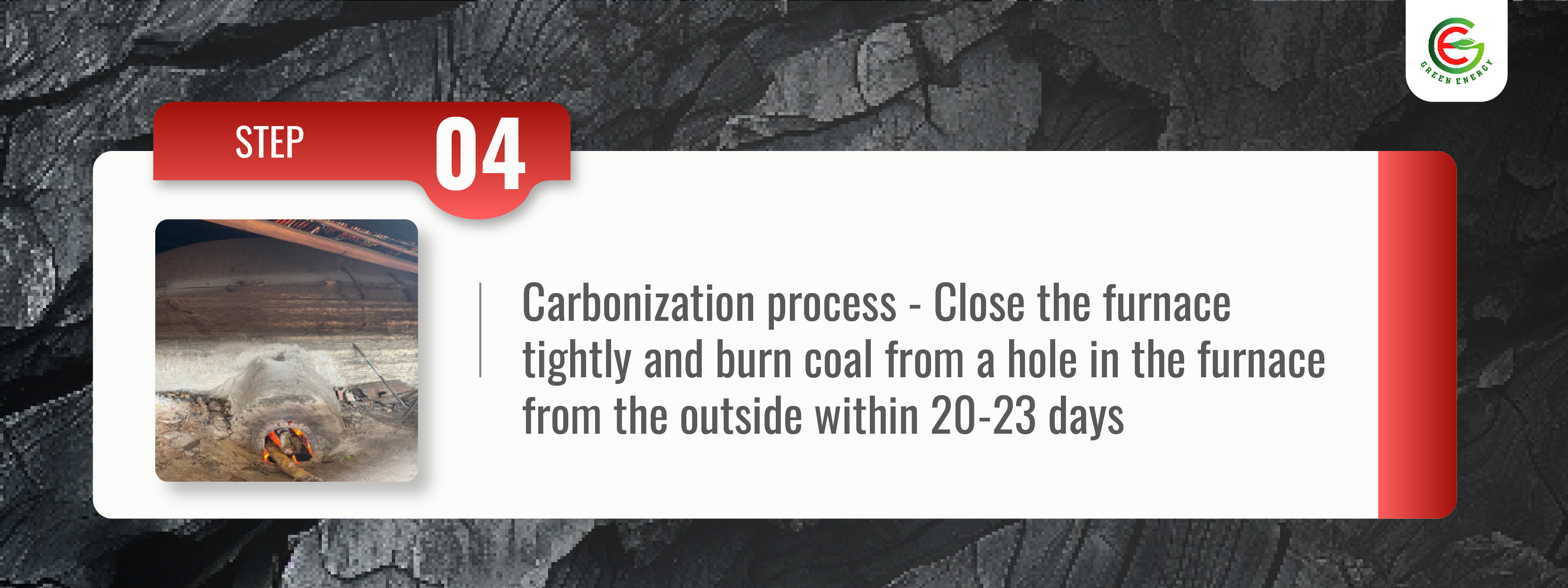

Step 4: Carbonization Process

The carbonization process is the most crucial stage in charcoal production, determining the quality of the entire batch. The kiln is sealed tightly to ensure no air enters, and heat is supplied from an external burn hole. This process lasts from 20 to 23 days, depending on the type of wood and weather conditions. The kiln’s temperature is closely monitored to ensure even burning and complete conversion of the wood to charcoal.

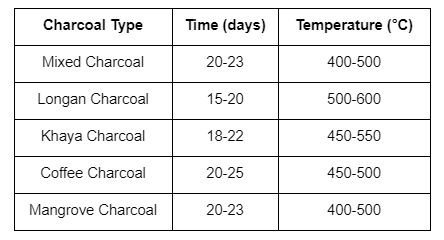

Below is a summary of the carbonization time and temperature for each type of charcoal:

Step 5: Cool the Charcoal

After the carbonization process is complete, the charcoal cooling process is carried out by stopping the burning and keeping the kiln tightly closed for about 8 to 10 days. Keeping the kiln sealed helps slow the cooling process and prevent oxidation, ensuring the charcoal has high hardness and quality.

Step 6: Open the Kiln and Take the Charcoal Out

Once the kiln has cooled sufficiently, we open the kiln and carefully take the charcoal out. Do not open the kiln too early, as sudden exposure to oxygen can cause the charcoal to ignite. The charcoal continues to cool outside for about 20 to 21 days to ensure it does not reignite when exposed to air. Slow cooling helps ensure the charcoal achieves the best hardness and quality.

Step 7: Evaluate and Classify Charcoal Quality Based on Sound and Texture

After the charcoal has completely cooled, we evaluate and classify its quality based on sound and texture. High-quality charcoal produces a sharp sound when lightly tapped, has a uniform color, and a solid structure that does not crumble. We also check other characteristics such as moisture and heat content to ensure the charcoal meets the highest quality standards.

Step 8: Cut the Charcoal to the Required Size and Store in a Cool, Dry Place

The classified charcoal is then cut into sizes according to customer requirements. The charcoal blocks are neatly and uniformly cut for easy use and transport. After cutting, the charcoal is stored in a cool, dry place to ensure the best preservation, avoiding moisture absorption that can reduce quality.

Step 9: Pack the Charcoal and Wait 5-7 Days Before Putting It into the Container

Finally, the charcoal is packed into bags or boxes of various weights such as 3kg, 5kg, 10kg, 15kg, 20kg,… to meet diverse customer needs. After packing, we leave the charcoal in storage for 5 to 7 days for a final check to ensure no smoldering before transferring it into the container and exporting.

With a modern and closed production process, Green Energy Inexp CO. is committed to providing customers with high-quality, environmentally friendly, and safe charcoal products. We are proud to be a leading charcoal supplier from Vietnam, ready to meet the needs of customers worldwide.

We have our own factory in Vietnam. Welcome to contact us!

GREEN ENERGY INEXP CO., LTD

Website: greenenergyinexp.com.vn

Email: info@greenenergyinexp.com.vn

Hotline: (+84) 90 601 10 18